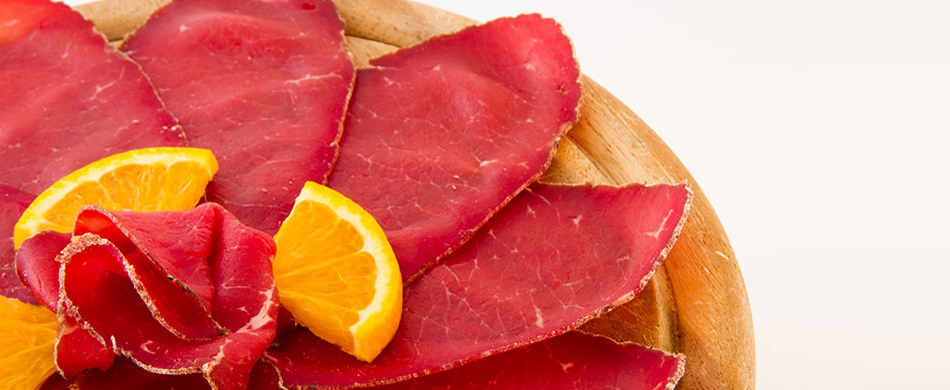

The Brisaola Alpi

The name Brisaola is derived from the local dialect of Livigno and Trepalle. It is a typical local product obtained from a particular traditional processing which Alpi still follows meticulously and with dedication.

Method of conservation

Method of conservation

It is recommended that Brisaola is stored in a cool and dry place, a cellar or better the refrigerator. Being a product subject to weight loss it is probable that with the passing of time the Brisaola dries thus making slicing difficult: to remedy we advise that the Brisaola is wrapped in a damp cloth, even soaked in red wine, and is held covered in this way.

If a characteristic flower can be seen, a mildew of greenish-grey colour, this can be removed with running water. One has to let it dry before proceeding with the slicing.

How we produce our Brisaola

Everything starts from the selection: in fact our Brisaola is made only with fresh meat carefully cleaned by filleting some cuts of the thigh (the tip of the hip) of bovine animals aged between 2 and 4 years, rigorously of breeds reared in the wild and unspoilt pastures.

Selection

Once selected, the meat is deposited in large stainless steel basins in which we add Red wine of Valtellina, salt, cinnamon, bay leaves, pepper, garlic, nutmeg and aromatic herbs of the area. We avoid any contamination of gluten: this consents Alpi’s Brisaola to be inserted in the handbook for coeliacs.

The Alpi Brisaola has been inserted in the celiac disease handbook since 2012: Gluten Free and suitable for every diet.

Marination

On alternate days specialized staff massages manually pieces to make them more "sweet" and to allow an improved penetration of the flavourings so that later on they can be inserted, after about two weeks, in special nets designed to shape the future Brisaola.

Massage

Subsequently the drying and aging begins: during this last phase our Brisaola distinguishes itself from all other similar meats. In fact, the fresh clean air of Livigno consents a traditional maturing without the need to bag the salami but by letting it breathe as directed by the tradition.

Curing and drying

A slow and controlled process thanks to an ultra-modern enthalpy plant (this system is the computerized transposition of external air in the aging premises: an operation that allows a truly natural drying). Given that our product is non-industrial, the seasoning phase lasts at least three weeks after which the Brisaola is packaged to be transported to your tables.

Technical innovation

Alpi follows with great care every aspect of quality control: from raw materials to slaughter, up to the entire production process. Where technology has helped us improve the results and the measurement we have availed ourselves of a computer system that helps us to control the aging process and to obtain the traceability of the product.

Quality control

Alpi s.r.l. - Via Compart, 561 - 23030 Livigno (SO)

Alpi s.r.l. - Via Compart, 561 - 23030 Livigno (SO)